1/4

Central Feening System

產品詳情

The central feeding system is designed for the production of plastic products in the injection molding workshop, achieving uninterrupted unmanned continuous molding operations. The variety of raw materials and the combination of multi-color materials can be changed as needed to achieve automation of the coloring process. The system is capable of fully automatic regeneration and use of injection port cold materials, controlling all feeding equipment, and preventing the occurrence of blockage in the storage bin. Full automation is achieved by setting up a central monitoring station.

What is the central feeding system

The central centralized feeding system adopts microcomputer centralized automatic control, achieving 24-hour continuous feeding operation for granular materials. Multiple small microcomputers control the coloring process of each molding machine, ensuring accurate measurement, uniform mixing, and flexible color change to meet the requirements of multiple colors and varieties of products. Flexibly change the material supply according to the production volume of different molding machines. Multiple supply pipeline designs can ensure diversified requirements for main materials. The system has a variety of monitoring and protection functions, job security and reliability. The aliases of the central feeding system include: centralized feeding system, automatic feeding system, etc.

The working principle of the central feeding system

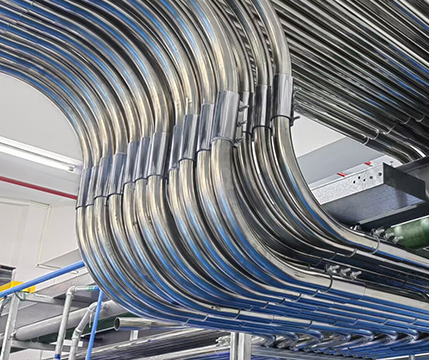

The central feeding system adopts a vacuum conveying method, which transports plastic raw materials from the storage tank to the central dehumidification and drying system through a centralized pipeline system, and then transports the dried raw materials to each injection molding machine. The central feeding system adopts a design method of "one machine, one pipe" to ensure that the air in the entire system transports the raw materials and prevents moisture regain after dehumidification and drying. At the same time, the operation of each transmission is stable and there is no occurrence of material blockage. It is used in conjunction with the central dehumidification and drying system, and can be used to clean the conveying pipeline after the dehumidification and drying circulation, ensuring that there are no residual particles in the pipeline. While avoiding moisture regain of the raw materials, it also ensures consistent performance of the raw materials added to the injection molding machine. Under the action of vacuum negative pressure, the original dust in the raw material will be filtered out through the dust filtration system, which helps to improve the quality of the formed product.

Composition of the central feeding system

Central console, cyclone dust collector, high-efficiency filter, fan, branch station, drying hopper, dehumidifier, material selection rack, micro hopper, electric eye hopper, cut-off valve, cut-off valve.

Characteristics of the central feeding system

1、 Efficient: The central material supply system can automatically supply various raw materials to any injection molding equipment in multiple rooms, including drying and color matching of raw materials, as well as proportional utilization of crushed and recycled materials. It can implement highly automated control, monitoring, and meet the production needs of 24-hour non-stop.

2、 Energy saving: The central feeding system is easy to operate, requiring only a few people to control the supply demand of the entire injection molding factory, thereby reducing a large amount of labor costs.

Secondly, the raw material belt and corresponding auxiliary equipment next to the injection molding machine have been reduced, and the utilization rate of space has been improved. In addition, due to the adoption of a central supply method, a significant reduction in the number of individual equipment has been achieved, resulting in savings in electricity and reduced maintenance costs.

3、 Personalization: The central feeding system can meet different user needs, workshop characteristics, and raw material usage requirements. We can design optimal solutions based on actual needs.

4、 Image of a modern chemical factory: The central feeding system will minimize the pollution of raw materials and dust on injection molding production, thereby maintaining a clean production workshop. The unique centralized dust recovery system of the central feeding system makes cleaning more convenient and environmentally friendly, meeting the requirements of a 100000 level clean room operation standard and reducing noise, ultimately achieving an unmanned automated production workshop, Establish an image of modern chemical plant management.

Design process of central feeding system

Raw materials → storage → measurement → drying → transportation → use

The central feeding system adopts a sealed circuit design with one machine and one pipe, ensuring stable operation of the entire system without any plastic moisture or blockage. It is used in conjunction with a central dryer (dehumidifier) system to allow dry air to re dry the raw materials, prevent moisture regain of the dried plastic, and clean the conveying pipes after each conveying cycle to ensure that there is no residue inside the pipes. While avoiding moisture regain in the raw materials, it also ensures the consistency of the materials added to the injection molding machine. Under the action of vacuum negative pressure, the original dust in the raw materials is filtered out through the filter (dust collector) system, which is beneficial for improving product quality.

Central console features:

1. Adopting PLC and large-sized 10.4-inch color human-machine interface touch panel, easy to understand and easy to operate;

2. Colored written display of various settings, operations, and operating conditions;

3. Equipped with material pipe evacuation and cleaning, automatic cleaning and dust collection, alternating automatic switching between central feeding hosts A and B, and manual material selection and error prevention functions;

4. Add a raw material control screen to monitor the raw materials, suction, shortage, and various abnormal phenomena of the central host (motor) used by each molding machine. Features of Puda central feeding host:

1. Design the motor without stopping to avoid frequent motor starts and resulting in wear and tear;

2. Equipped with a safety relief valve, when the movement pressure of the host is too high, the safety setting value is overloaded, and the relief valve automatically releases pressure to protect the motor;

3. The two feeding hosts A and B alternate, and have an automatic switching valve design to ensure the stability of raw material transportation.

Features of automatic reverse cyclone dust collector:

1. Design an integrated air filter and cyclone dust collector to efficiently collect dust with natural centrifugal force;

2. It can be attached with a high-pressure air storage tank and automatically clean the filter;

3. The dust collector is equipped with a shut-off valve, which can effectively move the dust of the dust collector without stopping the machine.

Characteristics of fast feeding station (branching station):

The branching station is composed of several branches, and the raw materials of the same branching pipe can be used by injection molding machines, with each branch having a quick head pressing to ensure airtightness; It can improve system efficiency and facilitate material replacement.

What is the central feeding system

The central centralized feeding system adopts microcomputer centralized automatic control, achieving 24-hour continuous feeding operation for granular materials. Multiple small microcomputers control the coloring process of each molding machine, ensuring accurate measurement, uniform mixing, and flexible color change to meet the requirements of multiple colors and varieties of products. Flexibly change the material supply according to the production volume of different molding machines. Multiple supply pipeline designs can ensure diversified requirements for main materials. The system has a variety of monitoring and protection functions, job security and reliability. The aliases of the central feeding system include: centralized feeding system, automatic feeding system, etc.

The working principle of the central feeding system

The central feeding system adopts a vacuum conveying method, which transports plastic raw materials from the storage tank to the central dehumidification and drying system through a centralized pipeline system, and then transports the dried raw materials to each injection molding machine. The central feeding system adopts a design method of "one machine, one pipe" to ensure that the air in the entire system transports the raw materials and prevents moisture regain after dehumidification and drying. At the same time, the operation of each transmission is stable and there is no occurrence of material blockage. It is used in conjunction with the central dehumidification and drying system, and can be used to clean the conveying pipeline after the dehumidification and drying circulation, ensuring that there are no residual particles in the pipeline. While avoiding moisture regain of the raw materials, it also ensures consistent performance of the raw materials added to the injection molding machine. Under the action of vacuum negative pressure, the original dust in the raw material will be filtered out through the dust filtration system, which helps to improve the quality of the formed product.

Composition of the central feeding system

Central console, cyclone dust collector, high-efficiency filter, fan, branch station, drying hopper, dehumidifier, material selection rack, micro hopper, electric eye hopper, cut-off valve, cut-off valve.

Characteristics of the central feeding system

1、 Efficient: The central material supply system can automatically supply various raw materials to any injection molding equipment in multiple rooms, including drying and color matching of raw materials, as well as proportional utilization of crushed and recycled materials. It can implement highly automated control, monitoring, and meet the production needs of 24-hour non-stop.

2、 Energy saving: The central feeding system is easy to operate, requiring only a few people to control the supply demand of the entire injection molding factory, thereby reducing a large amount of labor costs.

Secondly, the raw material belt and corresponding auxiliary equipment next to the injection molding machine have been reduced, and the utilization rate of space has been improved. In addition, due to the adoption of a central supply method, a significant reduction in the number of individual equipment has been achieved, resulting in savings in electricity and reduced maintenance costs.

3、 Personalization: The central feeding system can meet different user needs, workshop characteristics, and raw material usage requirements. We can design optimal solutions based on actual needs.

4、 Image of a modern chemical factory: The central feeding system will minimize the pollution of raw materials and dust on injection molding production, thereby maintaining a clean production workshop. The unique centralized dust recovery system of the central feeding system makes cleaning more convenient and environmentally friendly, meeting the requirements of a 100000 level clean room operation standard and reducing noise, ultimately achieving an unmanned automated production workshop, Establish an image of modern chemical plant management.

Design process of central feeding system

Raw materials → storage → measurement → drying → transportation → use

The central feeding system adopts a sealed circuit design with one machine and one pipe, ensuring stable operation of the entire system without any plastic moisture or blockage. It is used in conjunction with a central dryer (dehumidifier) system to allow dry air to re dry the raw materials, prevent moisture regain of the dried plastic, and clean the conveying pipes after each conveying cycle to ensure that there is no residue inside the pipes. While avoiding moisture regain in the raw materials, it also ensures the consistency of the materials added to the injection molding machine. Under the action of vacuum negative pressure, the original dust in the raw materials is filtered out through the filter (dust collector) system, which is beneficial for improving product quality.

Central console features:

1. Adopting PLC and large-sized 10.4-inch color human-machine interface touch panel, easy to understand and easy to operate;

2. Colored written display of various settings, operations, and operating conditions;

3. Equipped with material pipe evacuation and cleaning, automatic cleaning and dust collection, alternating automatic switching between central feeding hosts A and B, and manual material selection and error prevention functions;

4. Add a raw material control screen to monitor the raw materials, suction, shortage, and various abnormal phenomena of the central host (motor) used by each molding machine. Features of Puda central feeding host:

1. Design the motor without stopping to avoid frequent motor starts and resulting in wear and tear;

2. Equipped with a safety relief valve, when the movement pressure of the host is too high, the safety setting value is overloaded, and the relief valve automatically releases pressure to protect the motor;

3. The two feeding hosts A and B alternate, and have an automatic switching valve design to ensure the stability of raw material transportation.

Features of automatic reverse cyclone dust collector:

1. Design an integrated air filter and cyclone dust collector to efficiently collect dust with natural centrifugal force;

2. It can be attached with a high-pressure air storage tank and automatically clean the filter;

3. The dust collector is equipped with a shut-off valve, which can effectively move the dust of the dust collector without stopping the machine.

Characteristics of fast feeding station (branching station):

The branching station is composed of several branches, and the raw materials of the same branching pipe can be used by injection molding machines, with each branch having a quick head pressing to ensure airtightness; It can improve system efficiency and facilitate material replacement.